Home » Product Range » Torque Wrench

Torque Wrench

Torque Wrench

Torque wrench is now a must have tool for all garages and workshops. A torque wrench allows a user to precisely tighten a nut or a bolt to an optimum rotational force or torque.

Advantages of torque master® torque wrenches:

- Extra Heavy Duty: With the use of high strength alloy steel and precise heat treatment, the torque wrenches are built to last.

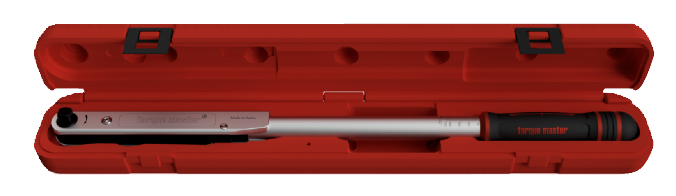

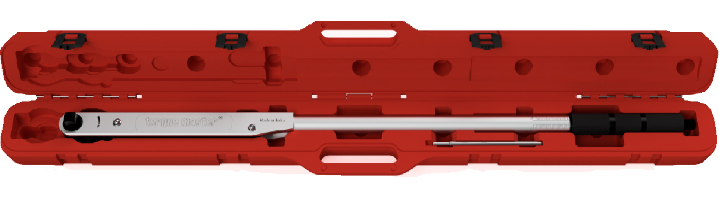

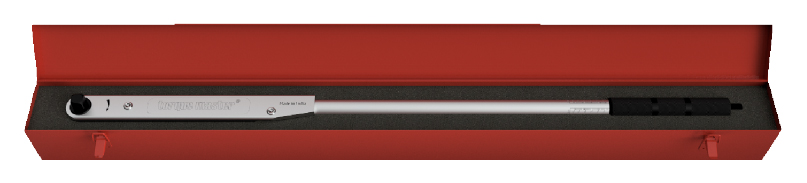

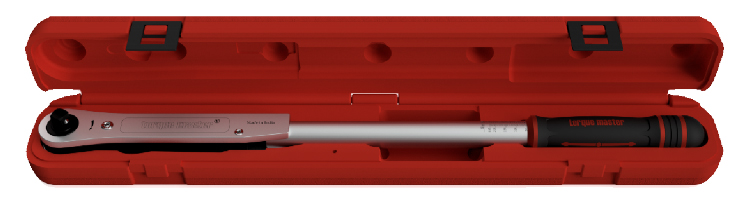

- Sturdy Storage: Supplied with an aesthetically pleasing rugged blow moulded case(Up to TM 750/750R) and with a sturdy steel case(above TM 750/R) for extra care and protection for your valuable tool.

- Accuracy: With a torque tolerance of ±3%, the accuracy exceeds any national or international torque standard including ISO 6789: 2017.

- Three phase mechanism: Sight, Touch and sound signal unmistakably lets the user know that the torque has been achieved even in a noisy environment.

- Comfort: The synthetic double moulded handle is manufactured by specially selected resin (Up to TM 250/TM 250R) which provides comfort and durability and resists chemicals in automotive and industrial usage. The new Ergonomic shape and higher proportion of soft feel high grip material make it a lot more comfortable.

- Bi-Directional torque: Torque can be applied in both right handed and left handed threaded nuts and bolts.

- Range: Covers a vast range from 2 Nm to 3450 Nm.

- Ideal for confined spaces: With the low re-engagement angle of 6 degrees for all ratchet type models, Working in confined spaces is not a hassle anymore.

- Available in both Standard and Ratcheting type. Production type and open end type can be supplied against specific orders.

During development, durability has been on top of our priority, both in terms of the life of the tool and the calibration of the tool. Full load torture tests are carried out on each and every torque wrench prior to dispatch. The result is a product that you can use with complete confidence that you have the best tool for the job.

Industrial Torque Wrenches

| Model |

Square Drive |

Range N.M |

L.C |

Range Lbf. Ft |

L.C |

Range Kgf.mts |

L.C |

Range Lbf.Ins |

Head Width |

Head Depth |

Approx. OAL at min cap. |

Weight Approx.(Kg) |

| TM 10 |

3/8” |

3-14 |

.5 |

2-10 |

.5 |

0.2-1.4 |

0.1 |

20-120 |

23 mm |

33 mm |

310mm |

0.600 |

| TM 25 |

3/8” |

5-35 |

2 |

5-25 |

1 |

0.5-3.5 |

0.2 |

40-300 |

23 mm |

33 mm |

340mm |

0.700 |

| TM 50 |

½” |

10-70 |

2 |

8-50 |

2 |

1-7 |

0.2 |

100-600 |

28 mm |

39 mm |

470mm |

1.00 |

| TM 100 |

½” |

25-135 |

5 |

20-100 |

2 |

3-14 |

0.5 |

250-1200 |

28 mm |

42 mm |

550mm |

1.30 |

| TM 160 |

½” |

50-220 |

5 |

40-160 |

5 |

5-23 |

1 |

450-2000 |

32 mm |

48 mm |

615mm |

2.40 |

| TM 250 |

½” |

70-340 |

10 |

50-250 |

5 |

7-35 |

1 |

600-3000 |

32 mm |

48 mm |

770mm |

2.70 |

| TM 300 |

¾” |

80-400 |

10 |

60-300 |

5 |

8-40 |

1 |

720-3600 |

32 mm |

55 mm |

780mm |

2.80 |

| Model |

Square Drive |

Range N.M |

L.C |

Range Lbf. Ft |

L.C |

Range Kgf.mts |

L.C |

Head Width |

Head Depth |

Approx. OAL at min cap. |

Weight Approx.(Kg) |

| TM 400 |

¾” |

135-540 |

15 |

100-400 |

10 |

14-56 |

1 |

48 mm |

62 mm |

1025mm |

6.50 |

| TM 500 |

¾” |

135-675 |

15 |

150-500 |

10 |

14-70 |

2 |

48 mm |

62 mm |

1030mm |

6.60 |

| TM 600 |

¾” |

200-815 |

15 |

150-600 |

10 |

20-84 |

2 |

48 mm |

62 mm |

1035mm |

7.10 |

| TM 750 |

¾” |

475-1015 |

20 |

350-750 |

20 |

49-105 |

2 |

48 mm |

62 mm |

1120mm |

7.90 |

| TM 750s |

1” |

475-1015 |

20 |

350-750 |

20 |

49-105 |

2 |

48 mm |

67 mm |

1120mm |

8.00 |

| Model |

Square Drive |

Range N.M |

L.C |

Range Lbf. Ft |

L.C |

Range Kgf.mts |

L.C |

Head Width |

Head Depth |

Approx. OAL at min cap. |

Weight Approx.(Kg) |

| TM 1000 |

1” |

540-1380 |

40 |

400-1000 |

20 |

55-140 |

5 |

56 mm |

84 mm |

1370 mm |

13.80 |

| TM 1400 |

1” |

1000-1900 |

50 |

750-1400 |

25 |

105-195 |

5 |

70 mm |

84 mm |

1410 mm |

15.50 |

| TM 2000 |

1” |

1350-2700 |

50 |

1000-2000 |

50 |

135-275 |

5 |

70 mm |

84 mm |

1550 mm |

19.00 |

| TM 2500 |

1” |

1550-3450 |

50 |

1150-2500 |

50 |

160-350 |

5 |

70 mm |

84 mm |

1650 mm |

22.00 |

| Model |

Square Drive |

Range N.M |

L.C |

Range Lbf. Ft |

L.C |

Range Kgf.mts |

L.C |

Range Lbf.Ins |

Swing Arc |

Head Width |

Head Depth |

Approx. OAL at min cap. |

Weight Approx.(Kg) |

| TM 10R |

3/8” |

2-14 |

.5 |

2-10 |

.5 |

0.2-1.4 |

0.1 |

20-120 |

06° |

38 mm |

39 mm |

320mm |

0.70 |

| TM 25R |

3/8” |

5-35 |

2 |

5-25 |

1 |

0.5-3.5 |

0.2 |

40-300 |

06° |

38 mm |

39 mm |

350mm |

0.80 |

| TM 50R |

½” |

10-70 |

2 |

8-50 |

2 |

1-7 |

0.2 |

100-600 |

06° |

43 mm |

42 mm |

460mm |

1.00 |

| TM 100R |

½” |

25-135 |

5 |

20-100 |

2 |

3-14 |

0.5 |

250-1200 |

06° |

43 mm |

48 mm |

560mm |

1.60 |

| TM 160R |

½” |

50-220 |

5 |

40-160 |

5 |

5-23 |

1 |

450-2000 |

06° |

43 mm |

48 mm |

620mm |

2.50 |

| TM 250R |

½” |

70-340 |

10 |

50-250 |

5 |

7-35 |

1 |

600-3000 |

06° |

43 mm |

48 mm |

780mm |

3.10 |

| TM 300R |

¾” |

80-400 |

10 |

60-300 |

5 |

8-40 |

1 |

720-3600 |

06° |

49 mm |

55 mm |

785mm |

3.20 |

| Model |

Square Drive |

Range N.M |

L.C |

Range Lbf. Ft |

L.C |

Range Kgf.mts |

L.C |

Swing Arc |

Head Width |

Head Depth |

Approx. OAL at min cap. |

Weight Approx.(Kg) |

| TM 400R |

¾” |

135-540 |

15 |

100-400 |

10 |

14-56 |

1 |

06° |

67 mm |

62 mm |

1095mm |

7.30 |

| TM 500R |

¾” |

135-675 |

15 |

100-500 |

10 |

14-70 |

2 |

06° |

67 mm |

62 mm |

1100mm |

7.40 |

| TM 600R |

¾” |

200-815 |

15 |

150-600 |

10 |

20-84 |

2 |

06° |

67 mm |

62 mm |

1105mm |

7.45 |

| TM 750R |

¾” |

475-1015 |

20 |

350-750 |

20 |

49-105 |

2 |

06° |

67 mm |

62 mm |

1200mm |

9.00 |

| TM 750sR |

1” |

475-1015 |

20 |

350-750 |

20 |

49-105 |

2 |

06° |

67 mm |

67 mm |

1200mm |

9.10 |

| Model |

Square Drive |

Range N.M |

L.C |

Range Lbf. Ft |

L.C |

Range Kgf.mts |

L.C |

Swing Arc |

Head Width |

Head Depth |

Approx. OAL at min cap. |

Weight Approx.(Kg) |

| TM 1000R |

1” |

540-1380 |

40 |

400-1000 |

20 |

55-140 |

5 |

06° |

95 mm |

84 mm |

1470mm |

17.50 |

| TM 1400R |

1” |

1000-1900 |

50 |

750-1900 |

25 |

105-195 |

5 |

06° |

95 mm |

84 mm |

1510mm |

18.80 |

| TM 2000R |

1” |

1350-2700 |

50 |

1000-2000 |

50 |

135-275 |

5 |

06° |

95 mm |

84 mm |

1650mm |

21.00 |

| TM 2500R |

1” |

1550-3450 |

50 |

1150-2500 |

50 |

160-350 |

5 |

06° |

95 mm |

84 mm |

1750mm |

25.00 |

TMT Torque Wrench

| Model |

Square Drive |

Range N.M |

L.C |

Range Lbf. Ft |

L.C |

Head Width (B) |

Head Depth (C) |

Gear Teeth |

Swing Arc |

Weight (Kg) |

Approx. OAL at min cap. (A) |

| TMT 50 |

3/8” |

10-50 |

0.25 |

8.29-37.8 |

0.184 |

30 mm |

32 mm |

72 |

5° |

1.00 |

360 mm |

| TMT 50S |

1/2” |

10-50 |

0.25 |

8.29-37.8 |

0.184 |

42 mm |

40 mm |

72 |

5° |

1.15 |

385 mm |

| TMT 100 |

1/2” |

20-100 |

0.5 |

16.59-75.60 |

0.37 |

42 mm |

40 mm |

72 |

5° |

1.30 |

435 mm |

| TMT 150 |

1/2” |

30-150 |

1 |

25.81-114.32 |

0.74 |

42 mm |

40 mm |

72 |

5° |

1.50 |

520 mm |

| TMT 200 |

1/2” |

40-200 |

1 |

33.19-151.20 |

0.74 |

42 mm |

40 mm |

72 |

5° |

1.50 |

520 mm |

| TMT 300 |

1/2” |

60-300 |

1 |

47.94-224.96 |

0.74 |

42 mm |

40 mm |

72 |

5° |

1.60 |

580 mm |

Salient Features:

• Dual Scale , Nm and Lbf ft

• Perfect lock with spring loaded pull down lock ring.

• Easy to read Torque Scales.

• 3/8” and 1/2” Square drive with quick release feature for easy socket change and sturdy socket retention.

• Accuracy: +-3% of indicated value which exceeds all International standard including ISO 6789:2017

• Calibrated in clockwise direction only.

Kaizen Series Light Weight Torque Wrenches

| Model |

Square Drive |

Range N.M |

Range Lbf. Ft |

Head Width |

Head Depth |

Weight (Kg) |

Approx. OAL at min cap. |

| KT 50 |

3/8” |

10-50 |

7.5-37.5 |

43 mm |

42 mm |

0.95 |

350 mm |

| KT 100 |

1/2” |

20-100 |

15-75 |

44 mm |

44 mm |

1.10 |

400 mm |

| KT 200 |

1/2” |

40-200 |

30-150 |

44 mm |

44 mm |

1.25 |

470 mm |

| KT 300 |

1/2” |

60-300 |

40-220 |

44 mm |

44 mm |

1.40 |

550 mm |

Kaizen Series Interchangeable Head Torque Wrenches

| Model |

Spigot |

Range N.M |

Range Lbf. Ft |

Weight (Kg) |

Approx. OAL at min cap. |

| KTi 50 |

16mm |

10-50 |

7.5-37.5 |

0.80 |

310 mm |

| KTi 100 |

16mm |

20-100 |

15-75 |

0.95 |

350 mm |

| KTi 200 |

16mm |

40-200 |

30-150 |

1.10 |

430 mm |

| KTi 300 |

16mm |

60-300 |

40-220 |

1.25 |

510 mm |

| MODEL NO. |

TORQUE CAPACITY |

SQUIRE DRIVE |

WEIGHT |

| KGF CM |

NM |

LBF IN |

| RANGE |

LC |

RANGE |

LC |

RANGE |

LC |

| TMSD 15 |

1-15 |

.5 |

0.1-1.5 |

.20 |

1-15 |

2 |

1/4" |

.350 KG |

| TMSD 50 |

10-50 |

5 |

1-5 |

.50 |

10-50 |

5 |

1/4" |

.600 KG |

| MODEL

NO. |

TORQUE

CAPACIITY |

FACTOR |

FEMALE

INPUT

Sq. Dr. |

MALE OUTPUT Sq. Dr. |

RECOMMENDED

TORQUE WRENCH |

| PLATE TYPE |

HANDLE TYPE |

LBFT |

KGM |

NM |

| TM-1 |

TMH-1 |

1250 |

170 |

1700 |

5 |

1/2 |

3/4 |

TM 250R |

| TM-2 |

TMH-2 |

1250 |

170 |

1700 |

5 |

1/2 |

1 |

TM 250R |

| TM-2/25 |

TMH-2/25 |

1250 |

170 |

1700 |

25 |

1/2 |

1 |

TM 100R |

| TM-5 |

TMH-5 |

2000 |

275 |

2750 |

5 |

3/4 |

1 |

TM 400R |

| TM-5/25 |

TM-5/25 |

2000 |

275 |

2750 |

25 |

1/2 |

1 |

TM 100R |

| TM-6 |

|

2500 |

345 |

3450 |

5 |

3/4 |

1.1/2 |

TM 500R |

| TM-6/25 |

|

2500 |

345 |

3450 |

25 |

1/2 |

1.1/2 |

TM 100R |

| TM-7 |

|

4500 |

622 |

6220 |

5 |

3/4 |

1.1/2 |

TM 400R |

| TM-7/25 |

|

4500 |

622 |

6220 |

25 |

1/2 |

1.1/2 |

TM 250R |

| TM-7/25 SD |

|

4500 |

622 |

6220 |

25 |

1/2 |

1.1/2 |

TM 250R |

| TM-7/125 |

|

4500 |

622 |

6220 |

125 |

1/2 |

1.1/2 |

TM 50R |

| TM-7/125 SD |

|

4500 |

622 |

6220 |

125 |

1/2 |

1.1/2 |

TM 50R |

| TM-9/25 |

|

7000 |

968 |

9680 |

25 |

3/4 |

1.1/2 |

TM 400R |

| TM-9/125 |

|

7000 |

968 |

9680 |

125 |

1/2 |

1.1/2 |

TM 100R |

| TM-11/25 |

|

1250 |

1734 |

17340 |

25 |

3/4 |

2.1/2 |

TM 500R |

| TM-11/125 |

|

1250 |

1734 |

17340 |

125 |

1/2 |

2.1/2 |

TM 160R |

| TM-13/125 |

|

35000 |

4845 |

48450 |

125 |

3/4 |

2.1/2 |

TM 400R |